Check out our Superior Patented Vent System

ACHIEVE BREAKTHROUGH COLORS with your Cress kiln Discover how good clean uncontaminated colors can be. Achieve pure, more natural colors with the new Cress Patented clean-air unit.

This system exhausts kiln fumes separately from the top, middle, and bottom of the kiln to prevent cross contamination of colors so they look their very best. It also keeps fumes out of your kiln room by venting them outside.

The exhaust fan automatically waits until the kiln turns on, then goes off when the firing is complete. When cooling, the fan turns back on at 1000ºF automatically and off at 140ºF for safe cooling to protect your pieces. This gives you the strongest properly annealed ware in the fastest possible time. Standard metal 4” dryer ducting is all that is required for the exhaust.

Kiln Vent Instructions:

- Line up the plug on the top of the fan box with the bottom of the control panel. Plug in the fan box.

- Hold the fan in place while gently clamping both the left and right clamps. Do not twist the fan during the clamping process. The plug is very delicate and will bend and/or break off if twisted.

- Attach your aluminum tubing to the fan box.

- The fan will operate when the kiln begins the firing process, and will stop when the firing process is finished, it will operate again between 1000° F and 130°F, to aid with cool down then it will turn off. At this point you can unload your kiln.

Operation:

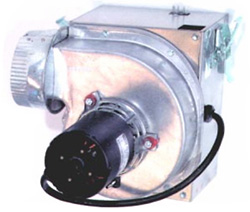

The CRESS Vent System prevents fumes from escaping from the kiln by creating a small negative pressure within the kiln body. The negative pressure is sufficient to prevent the escape of fumes, but does not cause excessive heat loss or cooling. The vent fan assembly attaches to the bottom of the kiln control panel. Fan ready kilns have pre-installed wiring that plugs into the fan assembly when it is attached. At the same time, the fan also draws air from inside the kiln body into the control panel. The air from inside the kiln body passes into the control panel through small holes in the kiln wall. The small amount of hot kiln air mixes with the room temperature within the control panel prior to being exhausted. For this reason the exhaust air remains relatively cool.

Venting Requirements:

Four inch metal dryer-type vent ducting is required to exhaust air to the outside.

Exhaust:

Air temperature of the exhausted air is approximately 20°F higher than the ambient room temperature.

Electrical Requirements:

The CRESS Vent System fan is supplied power through the control panel. The motor uses 220v power and draws .53 amps when operating.

Specifications:

Shipping weight is 15 pounds. Total airflow is 80 CFM. Maximum ducting distance: 70ft. Maximum number of bends is 4 sweeping bends. Motor: FASCO Industries, Inc., RPM 3000. CAS listing LR36496.

Use:

The vent system will come on at the beginning of a firing. Once the kiln has reached temperature the vent will turn off, then it will come back on at 1000° F to provide a slightly faster cooling rate. Then it will turn off when the kiln reaches 140°F. Now it is safe to unload your kiln and it is ready to fired again.

Agency Approvals:

The CRESS Vent System when used with a listed CRESS kiln is CSA listed and has been tested by CSA to the UL Standard 499. CSA is a nationally recognized testing laboratory.